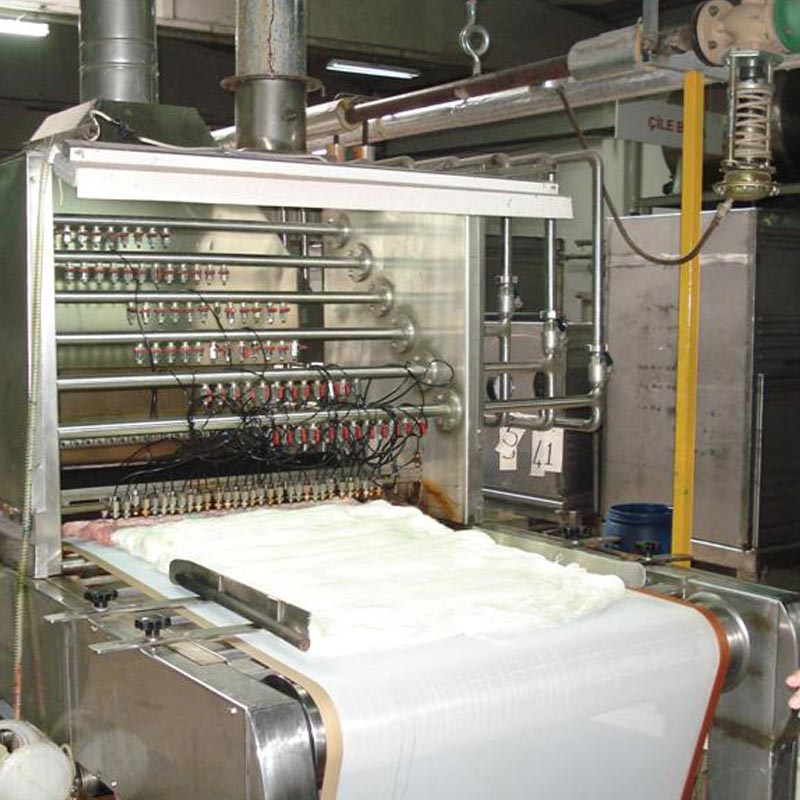

Continuous Multicolor Dyeing Machine

• It is designed for 6 color printing.

• Complete machine is manufactured from AISI 316 quality stainless steel.

• Machine band width is 1000 mm and machine height is 14.000 mm. Machine band speed can be adjusted upon good type by invertor speed control. Motor power is 1,5 kw.

• 98 - 100°C proper heat distribution with direct steam and PID temperature control opportunity.

• Maximum hank length will be 850 mm and machine capacity is 1OO-125 kg/ hour. Hank weight is 3OO or 4OO gr.

• Machine is constituted with multicolour, print, spraying (steaming cabin), showering (washing), softener providing and squeezing cylinders.

• Multicolour print can be performed upon spraying for mixture of wool, acrylic, viscon, nylon, polyester as hank.

• There will be 6 pipes and 72 dye nozzles (12 on each pipe) and spherical valve at the entrance of the machine.

• Spraying nozzle pressures are adjusted with spherical valves and can be observed with manometers located on each pipe.

• Processing liquor excess that is pumped is gained again to tanks.

• Spraying nozzles are american product. Washing and showering opportunity at the exit of spraying. Prevention of colour interference with strong vacuum that collects the waste dye on band.

• Absolute result in sensitive products with squeezing cylinders in which pressure can be adjusted.