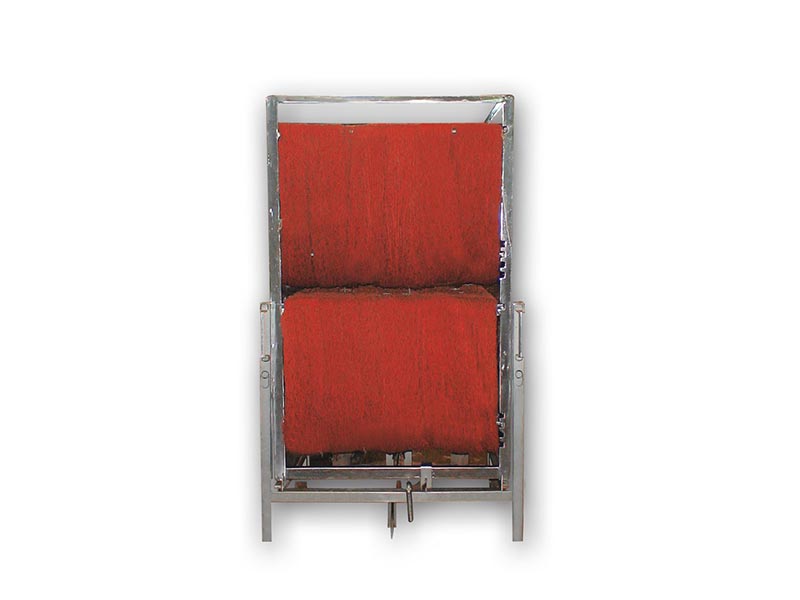

Hang Dyeing Machine

• All of the surfaces in contact with processing liquor will be manufactured from·6mm _AISI 316L stainless steel.

• Circulation pump located behind of the machine provides the main circulaton. It is inverter controlled and can run two-ways. It has silicon carbide mechanical seals.

• Cover locking system is performed pneumatically.

• One dye tank and injection pump that gives chemicals from dye tank to main tank.

• Heating and cooling inside the machine is performed with seperate serpentines.

• Liquor movement can be seen from the sight glasses, which are put to front covers.

• It’s most important advantage is that liquor volume and feeding ratio can be controlled. Low liquor ratio provides saving in operation water, steam and chemical amounts. More better dyeing by low liquor speed.

• There are both visual and electrial systems to control the water level inside the machine.

• There are electrical safety system that prevents the opening of the covers, when there is water and pressure inside the machine, even this is attempted from outside of the machine.

• Machine’s safety system is controlled with electrical safety prosestats and mechanical safety valves for sudden pressure increase inside the machine.

• It increases the penetration of dye in high circulation speeds and provides saving in dye usage.

• Operation time is shortened by having high heat.

• Reserve tanks provides important amount of energy and water saving.

• Opportunity of dyeing twice capacity in one charge with the same colour as it has coupling feature.

• It decreases water usage without changing bath ratio in air bag systems and provides ideal solutions for partial charges.

• Full automatic textile dyeing computer with easy usage in different brands upon request.

Capacities

- 3 KG. / ŞARJ

- 5 KG. / ŞARJ

- 30 KG. / ŞARJ

- 75 KG. / ŞARJ

- 150 KG. / ŞARJ

- 300 KG. / ŞARJ

- 600 KG./ ŞARJ